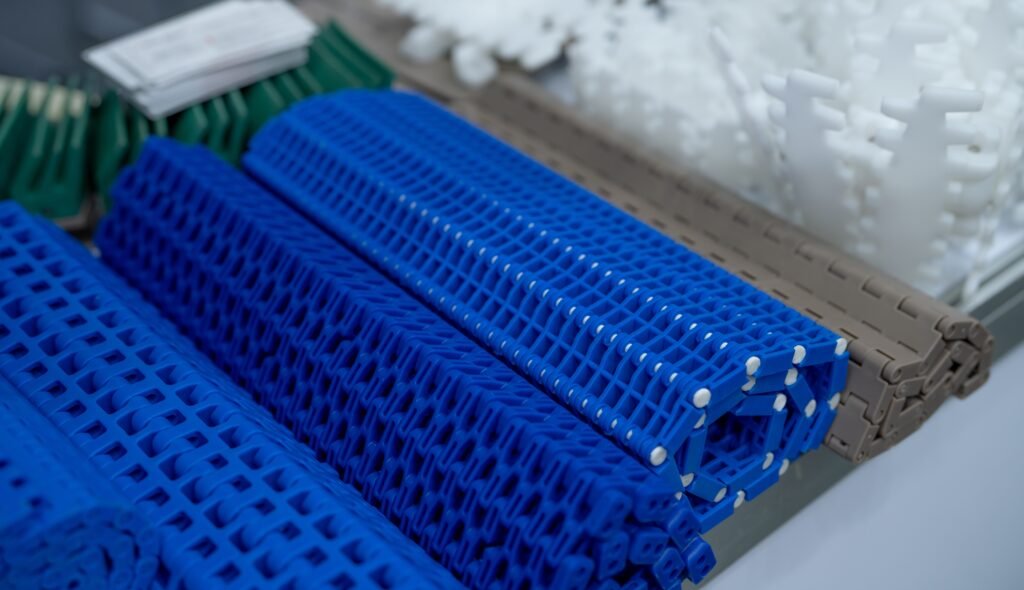

Plastic Modular Chain – Assembly Line Conveyor Solution

Product Overview

Our high-performance plastic modular chains are engineered for industrial assembly lines and manufacturing processes. Featuring precision-molded thermoplastic construction and interlocking design, these chains deliver reliable, cost-effective conveying solutions for factories across diverse industries.

Key Features

🔗 Superior Chain Design

- Precision-molded modular construction with secure interlocking system

- Self-tracking design eliminates belt wandering issues

- Flexible configuration adapts to straight runs, curves, and inclines

- Easy assembly and disassembly for quick maintenance

💪 Exceptional Durability

- High-strength engineering plastics resist wear and impact

- Temperature range: -40°C to +120°C

- Chemical resistant to oils, acids, and alkaline solutions

- UV stabilized for outdoor applications

⚙️ Versatile Performance

- Load capacity: Up to 150kg per meter

- Speed capability: 0.1-100 meters per minute

- Low friction coefficient reduces drive power requirements

- Quiet operation with noise levels below 60dB

🧽 Easy Maintenance

- Individual chain links replaceable without dismantling entire system

- Smooth surface prevents material buildup

- Dishwasher safe and steam cleanable

- No lubrication required – maintenance-free operation

Technical Specifications

| Parameter | Specification |

|---|---|

| Chain Width | 25mm – 1000mm |

| Pitch | 12.7mm, 19.05mm, 25.4mm, 38.1mm |

| Material | POM, PP, PE, Nylon |

| Working Load | 50-150 kg/m |

| Operating Speed | 0.1-100 m/min |

| Temperature Range | -40°C to +120°C |

| Color Options | White, Blue, Green, Gray, Black |

Industry Applications

🏭 Manufacturing Industries

- Automotive assembly lines

- Electronics production facilities

- Food and beverage processing

- Pharmaceutical packaging

- Textile manufacturing

📦 Material Handling

- Product assembly and testing

- Packaging and palletizing

- Sorting and distribution

- Quality control inspection

- Component feeding systems

Chain Types Available

Straight Running Chains

- Standard flat top chains

- Raised rib chains for product positioning

- Perforated chains for drainage

- Side-flexing chains for curves

Specialty Chains

- Magnetic chains for metal detection

- Anti-static chains for electronics

- FDA-approved chains for food contact

- Heavy-duty chains for high loads

Material Options

🔬 POM (Polyoxymethylene)

- Excellent dimensional stability

- High strength and stiffness

- Superior wear resistance

🧪 Polypropylene (PP)

- Chemical resistance

- FDA compliant for food applications

- Cost-effective solution

⚡ Nylon

- High impact strength

- Excellent fatigue resistance

- Self-lubricating properties

Installation & Support

🔧 Complete System Solutions

- Custom chain design and engineering

- Sprocket and drive components

- Support rails and guide systems

- Installation hardware and accessories

📋 Technical Services

- CAD drawings and 3D modeling

- Load calculations and system analysis

- Installation guidelines and training

- Preventive maintenance programs

Quality Assurance

✅ ISO 9001:2015 Quality Management System

✅ ISO 14001 Environmental Management

✅ REACH Compliance for European markets

✅ RoHS Directive compliance

✅ FDA Approved materials available

Competitive Advantages

💰 Cost-Effective

- Lower total cost of ownership

- Reduced maintenance expenses

- Extended service life reduces replacement frequency

🚀 Performance Excellence

- Smooth, reliable operation

- Minimal stretch and elongation

- Consistent tracking performance

🌍 Global Support

- Worldwide shipping capabilities

- Local technical support in major markets

- Comprehensive spare parts inventory

⚡ Fast Delivery

- Standard products ship within 48 hours

- Custom solutions delivered in 2-3 weeks

- Emergency replacement parts available

Customization Options

- Chain Width: Any width from 25mm to 1000mm

- Special Profiles: Custom top surfaces and attachments

- Color Coding: Multiple colors for process identification

- Material Grades: Specialized compounds for specific applications

Get Started Today

📞 Contact Information

📧 Email: [Your Email]

📱 Phone: [Your Phone Number]

🌐 Website: [Your Website]

📍 Address: [Your Company Address]

💬 Request Information

- Free technical consultation

- Custom design services

- Competitive quotations

- Sample chain sections available

📋 What We Need

- Application details and environment conditions

- Load requirements and conveying speed

- System dimensions and layout

- Special requirements or preferences

Transform your production line efficiency with our premium plastic modular chains. Contact our engineering team today for a customized solution that meets your specific manufacturing needs!

Industries Served Worldwide

- Automotive Manufacturing

- Food & Beverage Processing

- Electronics Assembly

- Pharmaceutical Production

- Logistics & Distribution

- Textile Manufacturing

Quality. Reliability. Performance. – Your Trusted Conveyor Chain Partner